DK Holdings Ltd

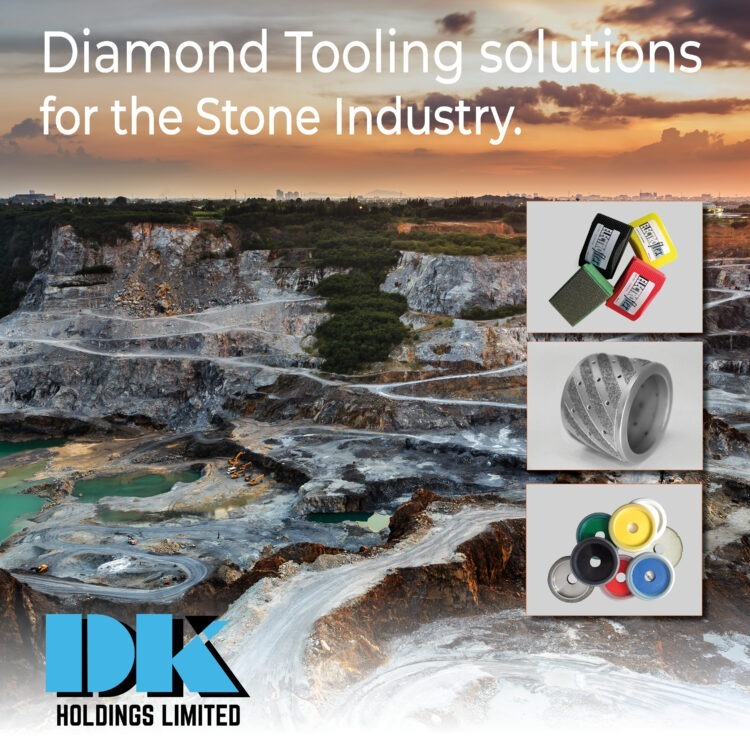

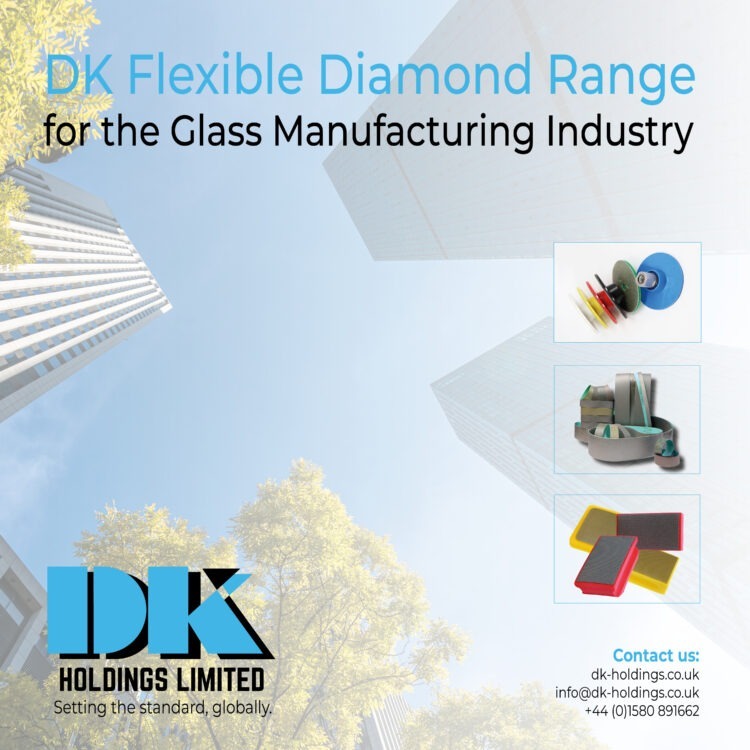

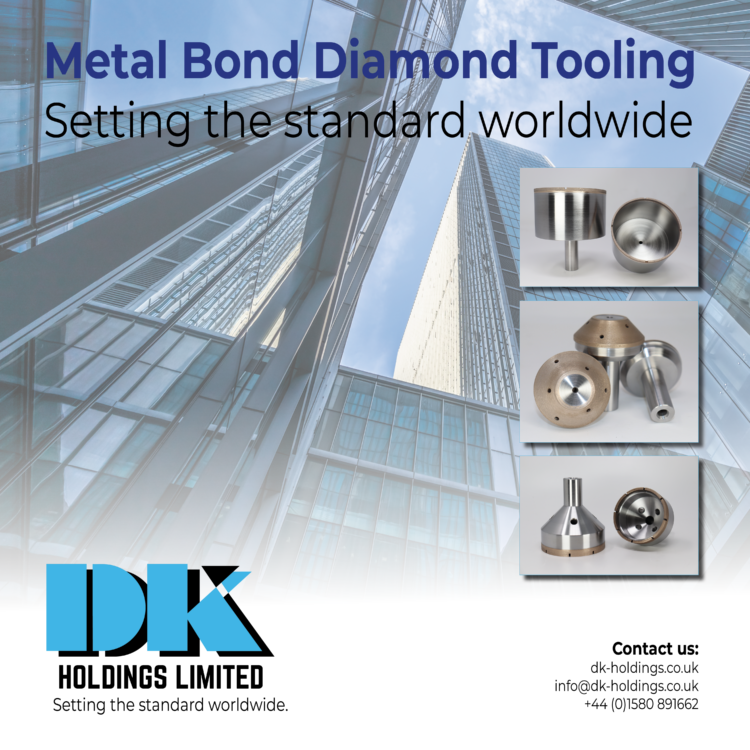

DK Holdings Limited is a specialist manufacturer and supplier of Diamond Tooling Solutions and Precision Engineered Components based in Staplehurst.

The expert team of engineers at DK Holdings can manufacture off-the-shelf and bespoke Diamond Tooling solutions across applications and industries such as aerospace, automotive, defence as well as the emerging renewable energy sectors globally.

Strip & Replate/Redress Services

Manufacturers are continuously looking to improve their green credentials whilst focussing on innovative improvements with their production processes. Using a Strip and Replate service can save up to 40% in tooling cost alone compared to buying a new product.

Additionally, the turnaround of a Strip and Replate service is a lot quicker than manufacturing a new bespoke tool.

By stripping and replating a Diamond Tool, old bodies can be reused which means no more throwing away piles of perfectly good steel bodies. Recycling at its best!!

We also offer a Redress service for a variety of multi-layer tools, such as metal or resin bond.

Precision Subcontracting

Utilising our 60+ years of manufacturing experience, we are expanding our production capabilities into precision subcontract component manufacturing from within our ISO-accredited production facilities in the United Kingdom.

Our production facilities now span 4.000 sqm and include manual, semi-automatic and CNC lathes, milling and grinding machines. The latest additions include multi-axis machining and twin spindle turning centres. Our machining capabilities and team of skilled engineers enable us to produce precision engineered components in a variety of materials such as aluminium, steel or tungsten carbide. Whilst cutting edge machinery is vital, we have a fantastic team of production staff, whose dedication, experience, and expertise are supported by our ISO 9001 accredited Quality Department.

So what is the secret of our success? Team DK’s philosophy is simple, work in partnership with the customer by listening to their unique requirements and utilising the machining capabilities and skillset of our expert team to come up with the desired result.

Whether you require a one-off special, small batch component manufacturing or a larger production run, we can support you, from inception to the supply.